Product Description:

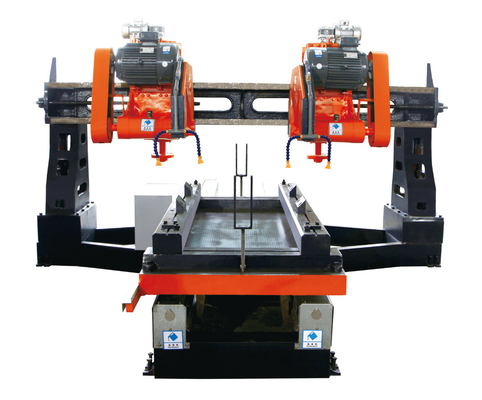

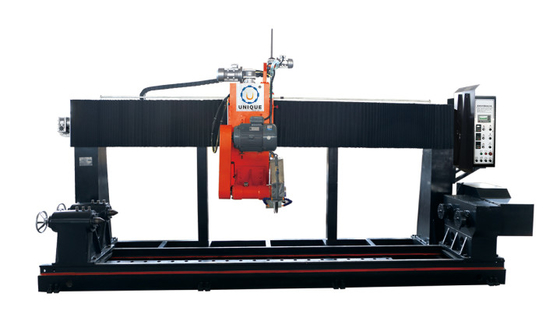

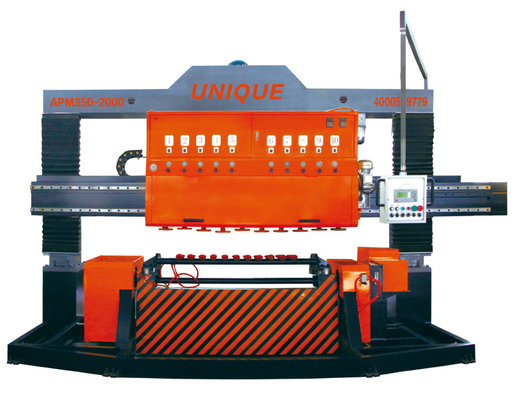

This machine adopts microcomputer control system, easy to operate;split structure, convenient and safe loading and unloading; the whole machinestructure is processed by CNC gantry machining center, and adoptshigh-precision linear guide rails, sliders, grinding-grade ball screws, andhigh-end servo systems, which greatly improves the stability, processing ac-curacy and production efficiency of the equipment. lt is suitable for processingvarious marble and granite slabs with high precision requirements.

Technical Parameter

| Parameter |

Unit |

ZDFT-600B |

ZDFT-600BL |

| Control system type |

/ |

PLC |

PLC |

| Blade diameter |

mm |

350-600 |

350-600 |

| Worktable size |

mm |

3200*2000 |

3200*2000 |

| Max processing size |

mm |

3200*2000*180 |

3200*2000*180 |

| Worktable tilting degree |

° |

0,85° |

0,85° |

| Cutting head rotation degree |

° |

0-360° |

0-360° |

| Cutting head rotation control mode |

/ |

Servo motor control |

Servo motor control |

| Cutting head charmfer rotating degree |

° |

Not |

0-60° |

| Main motor |

KW |

22(Parmanent magnet motors) |

22(Parmanent magnet motors) |

| Outline dimension |

mm |

6000*3500*3000 |

6000*3500*3100 |

| Water consumption |

m³/h |

2 |

2 |

Support and Services:

Our Product Technical Support and Services for the Bridge Saw Cutting Machine include:

- Installation and setup guidance

- Troubleshooting assistance

- Regular maintenance recommendations

- Software updates and upgrades

- Training sessions for operators

- Warranty information and claims processing

- Spare parts availability

Packing and Shipping:

Product Packaging:

Our Bridge Saw Cutting Machine is carefully packaged to ensure safe delivery to our customers. Each machine is wrapped in protective material and securely placed in a sturdy wooden crate to prevent any damage during transportation.

Shipping:

We offer worldwide shipping for our Bridge Saw Cutting Machine. Once your order is processed, our team will arrange for the machine to be shipped to your location using a reliable freight service. You will receive tracking information so you can monitor the status of your delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!