Round Ball Profiling Machine: Precision Shaping for Spherical Workpieces

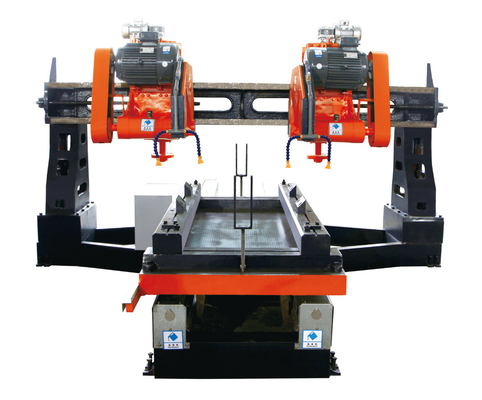

Revolutionize Stone Processing with the BRC-600 Round Ball Profiling Machine

In the realm of stone processing, precision, efficiency, and versatility are essential. The BRC-600 Round Ball Profiling Machine transforms how you handle rotary stone materials including vases, balls, column bases, and caps.

| Parameter |

Unit |

BRC-600 |

| Blade diameter |

mm |

400-600 |

| Max processing diameter |

mm |

600/1pcs |

| Max processing length |

mm |

1000 |

| Main motor |

kw |

15/18 (Optional) |

| Gross power |

kw |

20/23.5 (Optional) |

| Gross weight |

kg |

3500 |

| Outline dimension |

mm |

2900*1500*3200 |

| Water consumption |

m³/h |

2 |

Unmatched Structural and Technological Design

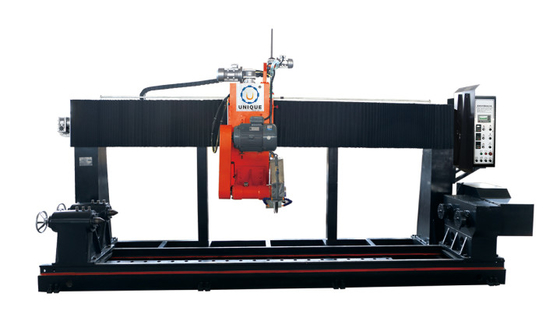

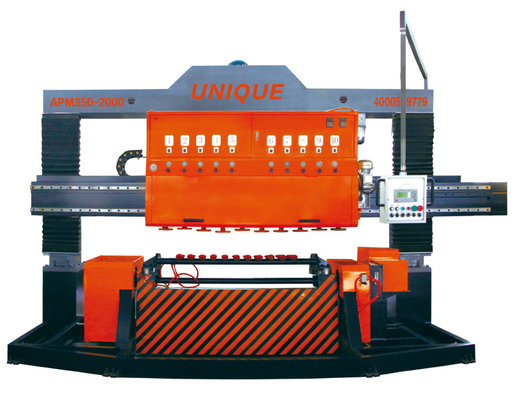

The BRC-600 features a gantry-type integrated structure that provides exceptional stability for precise cutting operations. The microcomputer control system enables accurate command execution, eliminating production inconsistencies.

Advanced optical fiber measurement technology ensures precise measurements, allowing the machine to create intricate shapes and perfect spherical profiles with ease.

Versatile Processing Capabilities

The BRC-600 handles various rotary stone materials including vases, balls, column bases, and caps. With a blade diameter range of Φ400-Φ600mm, it accommodates diverse project requirements. The machine processes workpieces up to Φ600mm in diameter and 1000mm in length.

Power and Efficiency

Equipped with an optional 15/18kW main motor and 20/23.5kW gross power, the BRC-600 handles demanding stone-cutting tasks efficiently. The machine maintains operational economy with water consumption of just 2m³/h.

With dimensions of 2900×1500×3200mm and weighing approximately 3500kg, the BRC-600 is designed for stable operation while fitting comfortably in production spaces.

Automated for Productivity

The BRC-600's fully automatic operation enables one operator to manage multiple machines simultaneously, reducing labor costs while increasing production efficiency. This automation eliminates the inconsistencies, high consumption, and poor precision associated with manual polishing.

The BRC-600 Round Ball Profiling Machine is an essential upgrade for stone processing operations, delivering advanced technology, versatile capabilities, and automated efficiency for higher quality products and increased profitability.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!