Product Description:

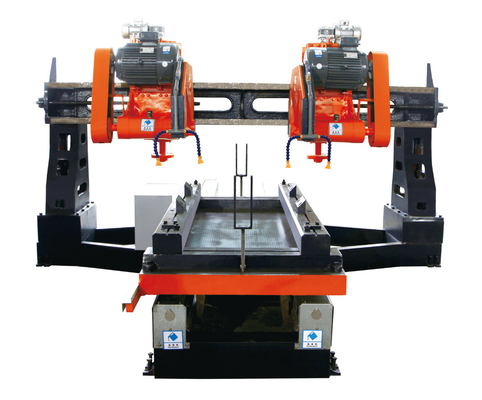

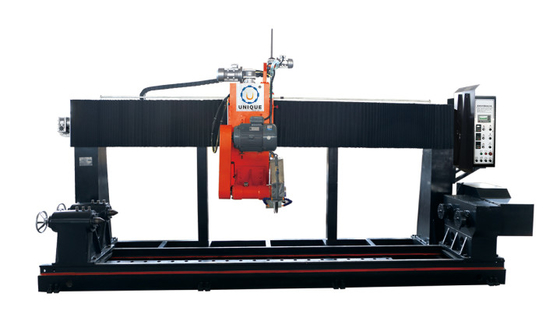

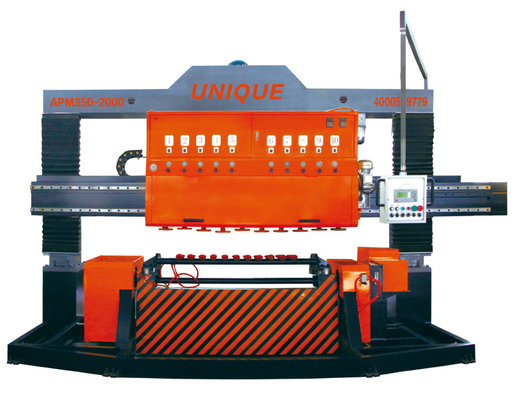

High-Accuracy Edge Trimming Solution

Engineered for stone, concrete, ceramics & composites, transforming rough edges into flawless finishes with unmatched efficiency.

Key Advantages

✅ Micron-Level Precision: ±0.1mm accuracy for complex profiles (luxury marble).

✅ 30% Faster Processing: Dual-drive motor system cuts cycle times, intelligent tension control reduces waste.

✅ Multi-Material Adaptability: Works on Mohs ≤9 materials (granite, quartz, precast panels, ceramics).

✅ User-Friendly Design:

- CNC touchscreen for 0°–45° angle/programming

- Dust-free operation (OSHA compliant)

- Modular structure for 50% faster maintenance

Technical Parameter

| Parameter |

Max processing size |

Wheel diameter |

Trolley size |

Table bearing weight |

Wire speed |

Main motor |

Outline dimension |

Gross weight |

Water consumption |

| BWT-3000-15 |

3000*3000*1500mm |

1600mm |

1600*2000mm |

20T |

0-40m/s |

11kw |

8800*5500*4100mm |

7200kg |

5m³/h |

| BWT-3500-18 |

3500*3000*1800mm |

1900mm |

1800*2000mm |

35T |

0-40m/s |

11kw |

9300*5900*4800mm |

9000kg |

6m³/h |

| BWT-3500-21 |

3500*3500*2100mm |

2200mm |

2000*2500mm |

50T |

0-40m/s |

15kw |

9800*6800*5600mm |

10700kg |

6m³/h

|

Applications:

Ideal for industries demanding precision edge finishing:

✅ Stone Fabrication

- Perfect for luxury countertops, monuments, & decorative stone—achieves smooth, uniform edges on granite/marble/quartz.

✅ Construction Materials

- Efficiently trims precast concrete panels, terrazzo slabs, & masonry blocks for architectural projects.

✅ Composite & Ceramic Manufacturing

- Processes high-strength composites (aerospace/automotive) and industrial ceramics with ±0.1mm accuracy.

✅ General Fabrication

- Versatile for soft-to-hard materials (Mohs ≤9), reducing manual rework across production lines.

Customization:

Tailor the machine to your unique needs:

✅ Material-Specific Configs

- Adjustable wire speed (10–50m/s) & blade types for granite, concrete, or composites.

✅ Size & Capacity

- Custom workpiece limits (up to 3000×2000×500mm) for large-scale projects.

✅ Automation Levels

- Semi-automatic or fully CNC-controlled interfaces to match production workflows.

✅ Regional Compliance

- Adapted for voltage standards (110V/220V/380V) and safety certifications (CE/UL).

Support and Services:

Our Product Technical Support and Services for the Diamond Wire Saw Machine include:

- Installation guidance and setup assistance

- Training programs for operators and maintenance personnel

- Troubleshooting and diagnostic support

- Regular maintenance schedules and recommendations

- Spare parts availability and ordering assistance

- Software updates and enhancements

- On-site technical assistance and repair services

- Customer service and product inquiries support

Packing and Shipping:

Product Packaging:

Our Diamond Wire Saw Machine is carefully packaged in a sturdy wooden crate to ensure safe transportation and delivery. The machine is securely placed and protected with foam padding to prevent any damage during shipping.

Shipping Information:

We offer worldwide shipping for our Diamond Wire Saw Machine. Once your order is confirmed, our team will process and ship the machine within 30 business days. Shipping times may vary depending on your location, but we strive to deliver your order as quickly as possible.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!