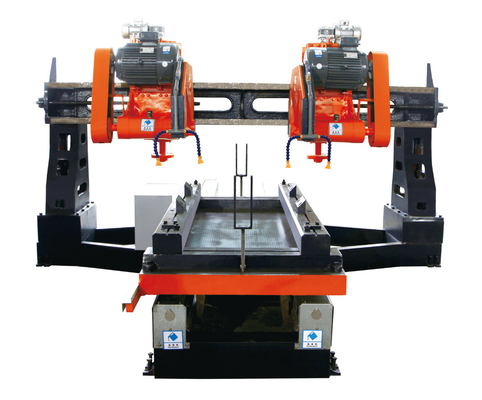

Precision Two Pcs Metal Column Cutting Machine For Roadblock, Pillar

Product Specifications

| Attribute |

Value |

| Power Consumption |

Low |

| Outline Dimension |

3500*1300*2800mm |

| Worktable Size |

1200*3500mm |

| Material |

Metal |

| Cutting Accuracy |

High |

| Max Processing Diameter(3 PCS) |

450-1400mm |

| Power Supply |

AC |

| Gross Power |

12.5kw |

Product Description

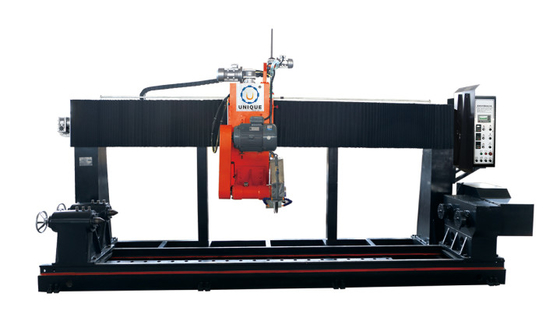

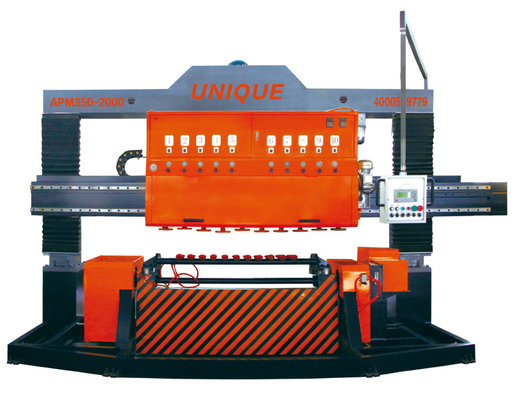

This machine adopts PLC / CNC control, three inverter, simple and practical structure, high efficiency. Dedicated to the processing of baluster, pillar, column base column caps, roadblock and others.

Key Features

- Product Name: Column Cutting Machine

- Gross Power: 16/20kw

- Noise Level: Low

- Material: Metal

- Cutting Speed: High

- Also known as a Polishing Machine in some applications

- Part of Stone Profiling Machinery category

- Ideal for Stone Profiling Machinery tasks

Technical Parameters

| Parameter |

Specification |

| Maximum blade diameter |

500mm |

| Maximum processing diameter |

250/2pcs,500/1pcs |

| Processing length |

50-2500mm |

| Outline Dimension |

4500*1500*3300mm |

| Main motor |

11/15kw(optional) |

| Gross weight |

4000kg |

| Gross Power |

16/20kw(optional) |

| Water consumption |

3m³/h |

| Control system |

PLC/CNC(optional) |

| Noise Level |

Low |

Applications

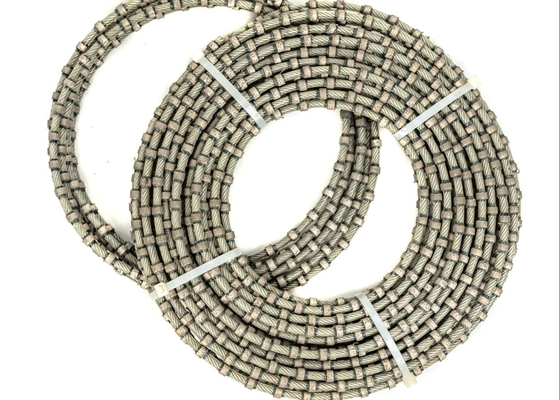

Designed for precision and efficiency, the SHM-200/400-2 is ideal for businesses in the stone processing industry. It falls under the category of Stone Profiling Machinery, making it perfect for sculpting and shaping various types of stones with high cutting accuracy. The machine's grinder functionality allows it to operate as a Grinder Machine, offering versatility in stone fabrication tasks such as profiling, cutting, and polishing.

Customization Options

Brand Name: XIANDA MACHINERY

Place of Origin: Jinjiang, Fujian, China

Certification: API, CCC, SONCAP, GOST, ISO, CE, SGS;IAF

Minimum Order Quantity: 1 SET

Price: To be negotiable

Packaging Details: Plastic Package, Suitable for Sea Transportation

Delivery Time: 1 month

Payment Terms: L/C, T/T, D/P, Western Union, Paypal, Money Gram, Others

Supply Ability: 1000 Sets/Year

Name: Column Profiling Machine

Noise Level: Low

Power Consumption: Low

Packing and Shipping

The Column Cutting Machine will be securely packaged in a robust, industrial-grade wooden crate designed to withstand the rigors of transportation. The crate will be internally padded with foam or other shock-absorbing materials to ensure that the machine is firmly held in place, minimizing the risk of movement and potential damage during transit.

Each package will include the Column Cutting Machine, an instruction manual, all necessary assembly tools, and any additional accessories specified in the purchase order. All items will be individually wrapped and securely placed within the crate.

Prior to shipping, the packaged crate will undergo a thorough inspection to guarantee that it is properly sealed and labeled with the correct shipping information, including the recipient's address and any pertinent handling instructions. The package will be shipped via a trusted freight carrier with experience in handling heavy industrial equipment, ensuring safe and timely delivery to the destination.

Upon dispatch, the tracking information will be provided to the customer to allow for real-time monitoring of the shipment's progress. Customers are advised to inspect the package upon arrival and report any signs of damage immediately for prompt resolution.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!